I was very impressed with Sissel's Lean Six Sigma knowledge. She makes it easy to identify improvements and create results.

Over 50 percent of all races won. With a smaller budget than competitors. The secret? 100 percent trust in data.

At Oslo Business Forum I heard Aksel Lund Svindal tell how the Norwegian alpine ski team won over 50 percent of all races.

With a smaller budget than their competitors.

The secret? 100 percent trust in data and in each other.

As Aksel said from the stage:

"It is measured in millimeters and a hundred of a second. If you are good or if you're not good enough, there's no discussion. It's numbers."

Right then it hit me: How many times have I experienced the opposite?

We discuss whether the numbers are correct, not how to improve.

Situation: The Norwegian alpine ski team won over 50 percent of all races with a smaller budget than competitors, based on 100 percent trust in data.

Insight: When the team doesn't trust the data, numbers become a cushion instead of a tool. With good data you go directly to action. With bad data you spend time discussing whether the numbers are correct.

Signs to watch for: The team discusses whether numbers are correct instead of what to do. Numbers are used as excuses. Meetings are about defending data, not improving the process.

Next step: Evaluate the measurement system. Can it actually distinguish good from bad performance? Is variation in measurement greater than the difference you're trying to detect?

What this is about: Trust in data determines whether teams spend time on discussion or action. When the measurement system isn't reliable enough, the team loses trust in the numbers and in each other.

Why it happens: The measurement system varies more than what you're trying to measure. The smallest unit is too coarse. The team has experienced incorrect numbers before, so they no longer trust them.

How you recognize it:

• The team says "That can't be right, we're much better than this"

• You spend more time discussing whether numbers are correct than what to do

• Numbers become an excuse instead of basis for improvement

• Meetings are about defending deviations, not solving them

You cannot build trust on data you cannot rely on.

The alpine team had no discussion about the numbers. They trusted the data and had 100 percent trust in each other.

They shared experiences from their race, even when it meant losing gold to a teammate. Because 100 percent trust requires 100 percent honesty. If you're not honest, the data will expose you.

As Aksel said:

"If you don't have good data, there'll be discussions around the table. If you have good data, you go straight to execution."

With good data you go from deviation to action. With bad data you go from deviation to discussion.

What if the timing in alpine skiing wasn't good enough?

What if the smallest unit was tenths, not hundredths of a second? What if variation in measurement overshadowed differences in performance?

How long would the trust last?

The answer: Not long.

Because the measurement system must be reliable enough to distinguish performances. Otherwise the numbers become meaningless.

Maybe you're not in alpine skiing. But I bet you recognize the dynamic:

• You discuss whether the deviation is real instead of solving it

• The team uses numbers as an excuse: "The measurement must be wrong"

• Operators don't trust the sensors: "It always shows wrong"

• Quality data is ignored because "we know the process is running well"

• Management asks "Are you sure this is correct?" instead of "What do we do about this?"

The consequence? You spend time discussing the numbers, not improving the process.

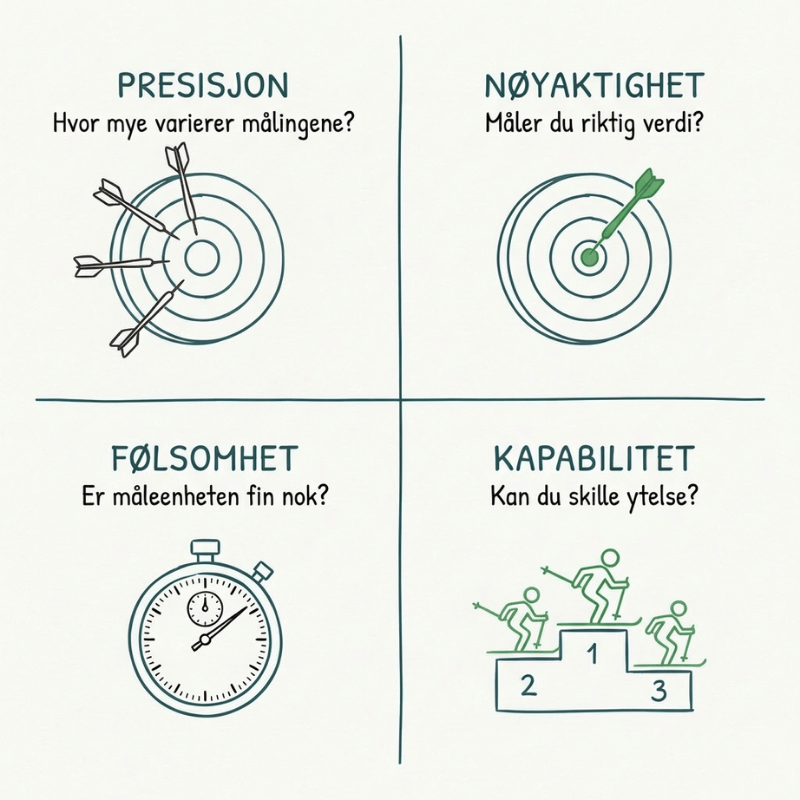

To know if your data is good enough, you must understand the measurement system's properties:

Precision (repeatability): How much do measurements vary when you measure the same thing multiple times?

Accuracy: Do you measure the correct value, or is there systematic deviation?

Sensitivity: Is the smallest unit fine enough? Like hundredths of a second in alpine skiing.

Capability: Can the measurement system actually distinguish between good and bad performance? Like distinguishing the performances of different alpine skiers.

Step 1: Ask the critical question

Are you discussing whether the numbers are correct, or what to do? If the answer is the former, you have a measurement system problem.

Step 2: Evaluate the measurement system's capability

Is variation in measurements greater than the difference you're trying to detect? Test by measuring the same object multiple times. If results vary significantly, you cannot trust them.

Step 3: Build trust through reliability

As Aksel said: "I believe good data and good use of data is a key element to building trust." Start by ensuring your measurement system can actually distinguish good from bad performance.

How do I know if my measurement system is good enough?

Test repeatability: Measure the same object multiple times. If results vary significantly, the measurement system isn't reliable enough. Rule of thumb: Measurement system variation should be under 10 percent of total variation you see.

What's the difference between precision and accuracy?

Precision is about how similar results are when you measure the same thing multiple times. Accuracy is about how close you are to the true value. You can be precise without being accurate, and vice versa.

How do I build trust in data within the team?

Start by ensuring the measurement system is actually reliable. Then: Be transparent about uncertainty, involve the team in testing the measurement system, and consistently show that numbers are correct over time.

What do I do if the team doesn't trust the data?

Find out why. Have numbers been wrong before? Is the measurement system unreliable? Do they lack understanding of what's being measured? Address the root cause, don't just say "you must trust the numbers."

Do I need MSA for all measurements?

No, prioritize measurements used for important decisions. If a measurement determines whether product is approved or rejected, you must know the measurement system is reliable. For less critical measurements, requirements can be lower.

This story is from our weekly newsletter, where we share experiences. Short stories for those who want to solve problems at the root and achieve measurable, lasting value creation.

Sign up for our newsletter:

If you want to learn more about the topics in this post:

• How to find root causes instead of treating symptoms

• Understand the difference between noise and signal with statistical process control

• Before you chase process errors, check the measurement system

Lean Tech AS | Kristoffer Robins vei 13

0047 481 23 070

Oslo, Norway

L - Look for solutions

E – Enthusiastic

A – Analytical

N - Never give up