I was very impressed with Sissel's Lean Six Sigma knowledge. She makes it easy to identify improvements and create results.

Fever, painkillers and antibiotics. One solves the problem. The other two only hide it temporarily.

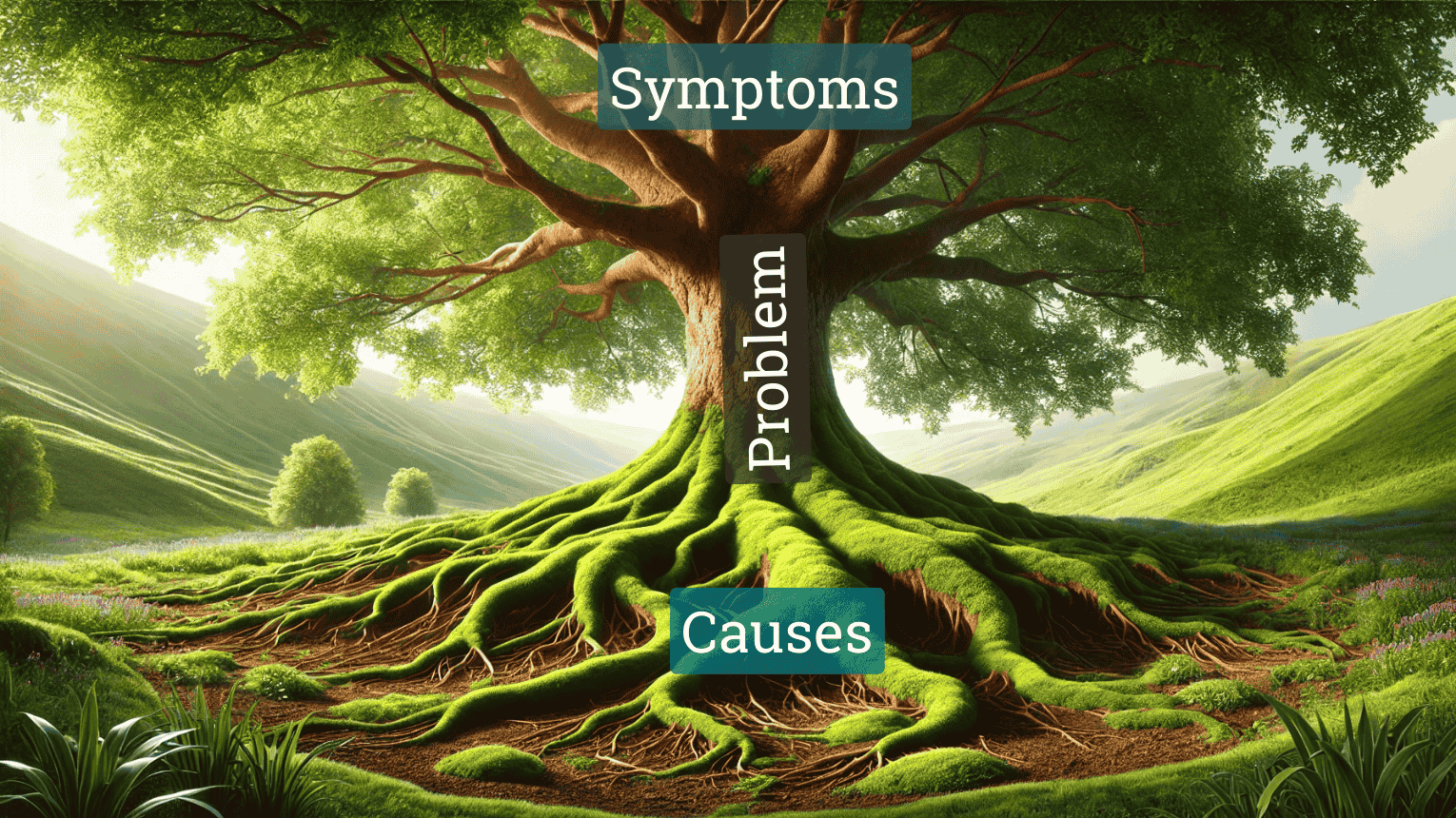

As the picture illustrates, a problem (the tree) can have many causes (roots). Over time, the symptoms (leaves of the tree) and the problem (tree) grow larger and become more visible.

Focusing on the leaves makes it difficult to get clarity of the problem and identify the true root causes.

The sequence matters: First understand the problem. Then investigate causes. Finally, implement solutions.

If you treat symptoms without addressing root causes, symptoms will reappear.

Situation: Problems may have multiple causes. Symptoms are visible, but root causes are often hidden like roots underground.

Insight: Treating symptoms gives temporary relief but doesn't solve the problem. For lasting solutions, you must address root causes. The frequency of the problem determines which strategy to use.

Signs to watch for: Same problem keeps coming back. Quick fixes don't last. Team treats symptoms instead of investigating causes.

Next step: Determine if the problem is due to normal or special cause variation. Use appropriate tools based on problem frequency and type.

What this is about: The difference between treating symptoms and solving root causes. Same principle applies whether you're treating fever or fixing production problems.

Why it happens: It's faster to treat symptoms than investigate causes. Quick fixes feel productive, even when they don't last.

Example: Fever as a problem

Taking painkillers if you have a fever reduces the symptom, but the root cause is not addressed.

If the fever is caused by an infection, you must address the root cause to become recovered. Antibiotics may be one solution, but the key is identifying the root causes first, then choosing the right treatment.

The same applies for problem solving in production: First identify the root causes, then choose the appropriate solution. Treating symptoms gives temporary relief. Solving root causes gives lasting results.

The causes of a problem can be complex and due to several factors. How often does it occur? Is it a single event?

The frequency of the problem is crucial when deciding problem solving strategy.

This is where Statistical Process Control becomes essential.

Statistical Process Control (Control Charts) separates normal and special cause variation. To succeed with your root cause analysis, it is crucial to know if the problem is due to normal or special cause variation.

Special cause variation: You can look for one specific abnormal event that caused the problem. It follows a linear cause-effect chain (more about this in the article "Carrot or Tree?").

Normal variation: The sum of variation from EVERYTHING that affects the process. To reduce normal variation, identify the variables that are most important to the outcome of the process. Process mapping will help you understand your process better.

Once you understand which variables affect the process, you can use observation and data to investigate what's most important. Analyzing data using graphical analyses, regression and hypothesis testing can help you determine what is critical. Sometimes observation is enough. When you know what's important, you reduce the variation of the critical variables, monitor and control them.

Critical mistake: If you react to normal variation as if it was special cause variation, you will probably make things worse.

Maybe you're not treating fever. But you probably recognize the dynamic:

• Same problem keeps coming back despite multiple "fixes"

• Team jumps to solutions without investigating root causes

• Quick fixes are celebrated, but problems reappear weeks later

• You react to every deviation without knowing if it's normal or special cause variation

• Corrective actions make the process more unstable, not less

The consequence? You spend time treating symptoms, not solving problems.

Here are tools to help you with root cause analysis:

Structure the analysis:

• Thought map, A3 or project charter to structure your problem-solving.

Determine variation type:

• Statistical Process Control determines if normal or special cause variation is causing the problem. Or maybe it's not variation but centering - SPC will tell you that as well.

Identify possible causes:

• Process Mapping identifies possible root causes

• 5 Why and Fishbone identify possible root causes

Prove root causes:

• Graphical analysis can prove root causes

• Hypothesis testing proves root causes when graphical analyses are not clear

Optimize and control:

• Correlation and Design of Experiment (DOE) determine optimal factor values

• Statistical Process Control (Control Chart) monitors variation of critical variables and ensures lasting solution

These tools are used within Lean Six Sigma's problem-solving method DMAIC:

Define: Understand problem and set goals

Measure: Map current situation

Analyze: Prove root causes

Improve: Solve root causes

Control: Create lasting results

At Lean Tech we use the FAST method (Focus, Analyze, Solve, Track) - a simplified, faster version of DMAIC for everyday problem-solving.

What's the difference between symptoms and root causes?

Symptoms are the consequences of a problem. They're what you see and experience (leaves on the tree). As time goes by, the symptoms (consequences) will increase. Root causes are the underlying factors creating the problem (roots). Treating symptoms gives temporary relief. Solving root causes gives lasting results.

How do I know if I should use 5 Why or SPC?

Use SPC first to determine if the problem is due to normal or special cause variation. You can also ask how often this happens, as described in this article. If special cause, use 5 Why to find the abnormal event. If normal cause, use process mapping and analysis to reduce variation from multiple sources.

What if the same problem keeps coming back?

You're treating symptoms, not root causes. Stop, use SPC to understand variation type, map the process, prove root causes with data, then implement lasting solutions.

When should I use hypothesis testing vs graphical analysis?

Start with graphical analysis. It's faster and often clear enough. Use hypothesis testing when patterns aren't obvious or when you need statistical proof for important decisions.

Do I always need to go to the root cause?

Not always. In healthcare, pain medication treats symptoms when root causes can't be cured. In production, you might include scrap costs in pricing when equipment replacement costs more than the scrap. Sometimes symptom management is the pragmatic choice. The key is making this decision consciously after analysis, not by default.

This article explains the tools for root cause analysis. For systematic problem solving, we offer courses in Lean Six Sigma methodology.

Sign up for our newsletter:

If you want to learn more about the topics in this post:

• Learn systematic problem solving in Green Belt course

• Separate signal from noise with statistical process control

• Why teams must agree on the problem before solving it

Lean Tech AS | Kristoffer Robins vei 13

0047 481 23 070

Oslo, Norway

L - Look for solutions

E – Enthusiastic

A – Analytical

N - Never give up